|

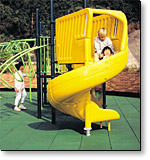

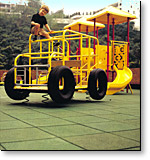

OTS provides two types of playground rubber surface systems: G-Flex Playground Tiles and Poured-in-Place Surfacing Components. G-Flex Playground Surface TilesOur playground surface tiles combine safety, simplicity, and cost effectiveness with ease of installation and maintenance. They are easier to install and repair than poured-in-place surfaces, and less expensive to maintain than wood fiber, sand, or other loose-fill alternatives.

G-Flex SBR Playground TilesOur recycled rubber playground surface tiles are available in three standard colors: Terra Cotta Red, Hunter Green, and Basic Black. Made from 100% recycled, shredded tires, each granule is mixed and coated with a pigmented binder during manufacturing.G-Flex EPDM-topped TilesOur EPDM-topped tiles come in a wide variety of vibrant colors, or may be custom made to your specifications. The cushion layer is made from recycled rubber, and the top layer is made from virgin, EPDM rubber. A bit more expensive than the SBR tiles, EPDM rubber is known for its exceptional color retention and UV stability. Color will not rub off onto clothing. RequirementsAlways specify the right surfacing for the critical fall height of your play equipment. Standard tile dimensions: 20 x 20

Accessories

WearmatsWe offer two types of wearmats for use in high-traffic areas such as underneath swings and slides. Our 1 thick mat (40 square) is perfect for use on playgrounds surfaced with engineered wood chips or loose-fill materials. Our 1.5 thick mat (40 square) has a beveled edge around all four sides, and is ideal for single use. Both types are available in Black only. Poured-in-Place Surfacing ComponentsOTS carries in stock 24 different colors of EPDM granules, as well as shredded SBR rubber for surface cushion layers, and several types of polyurethane binders to meet your needs. All three products may be combined to your specifications, packaged together, and drop-shipped to your individual jobsite.

EPDM Granules

Make your own mix with the Granules Mixer SBR RubberOur SBR rubber granules are used to construct the base or cushion course of the poured-in-place surface. Packaged in 50# bags, they are typically stacked 40 bags to the pallet. Granule size 3/8. BTR Polyurethane BindersQuite simply, we carry the best binders in the business. OTS binders are formulated specifically for the Pour-in-Place surfacing industry for the bonding of rubber resilient surfaces. It is manufactured with a proprietary castor oil based polyol and a non-solvent based wetting agent that lowers the trowel drag coefficient during installation.

BTR binders are shipped in sealed containers and must be protected against moisture. |

Accessible Navigation

Connect with Us!

Search Our Website

Make your own mix with the Granules Mixer

Main Navigation

OTS Manufacturing & Supply, Inc.

work

293 Industrial Dr.Lexington, SC 29072 US

Call Us:

803-957-3549 (work)

Fax:

803-356-9713 (fax)

©2025 OTS Manufacturing & Supply, Inc. All rights reserved.

View Accesskeys

Accesskeys

This site contains a number of keyboard shortcuts, called "accesskeys," to assist in navigating. Each Internet browser has a different method of accessing these keys:

- Internet Explorer on a PC use ALT+Accesskey

- Firefox on PC use ALT+SHIFT+Accesskey

- Firefox and Safari on Apple or Linux use CTRL+Accesskey

Please note: Internet Explorer users may also need to hit the “enter” key to activate a link. Apple users with Spaces enabled may need to use the accesskey for Skip to the main navigation (A); then, TAB through the navigation and press "enter" to activate a link.

Page navigation

- 0 : Back to Home

- 1 : Home

- 2 : Product Overview

- 3 : Technical Data

- 4 : Contact Us

Page jumping

- ? : View Accesskeys

- A : Skip to the main navigation

- C : Skip to the content

- S : Skip to the side bar

Available accessories include beveled edges, handicap ramps, and curbs to provide safe transition from playground rubber surface tiles to surrounding areas. EPDM-topped tiles may be inlaid with graphics of your choice (numbers, letters, stars, etc.) to personalize your play area.

Available accessories include beveled edges, handicap ramps, and curbs to provide safe transition from playground rubber surface tiles to surrounding areas. EPDM-topped tiles may be inlaid with graphics of your choice (numbers, letters, stars, etc.) to personalize your play area. We provide only the finest quality EPDM peroxide cured granules. All colors are weatherproof, UV ray resistant, and resistant to ageing. Our EPDM granules come packaged in 55# bags, and are typically stacked 40 bags to the pallet (of course, you may order a single bag or a truckload.) Granule size is 1-3.5mm. We encourage you to come play with our granules mixer, and check out what your color mix will look like before you finalize your design.

We provide only the finest quality EPDM peroxide cured granules. All colors are weatherproof, UV ray resistant, and resistant to ageing. Our EPDM granules come packaged in 55# bags, and are typically stacked 40 bags to the pallet (of course, you may order a single bag or a truckload.) Granule size is 1-3.5mm. We encourage you to come play with our granules mixer, and check out what your color mix will look like before you finalize your design.